KPB has calculated the impact of the planned hydrogen plant at Langstranda in terms of new economic activity and jobs. The analysis shows that GreenH’s project will create up to 800 man-years, half of which will be in Bodø or Salten.

– We asked KPB to calculate the effects of our plant, and now we see that this can have a major impact on Bodø. GreenH will focus on the use of local suppliers both in the construction phase and when the plant goes into production. For us, it’s important to have local and sustainable production and distribution of hydrogen. We will utilize all resources and by-products, and give back as much as possible to Bodø and Salten, says Ida Synnøve Bukkholm, business developer at GreenH.

According to the innovation and analysis company KPB’s analysis, the total employment effects for GreenH Bodø will be 700 annual jobs. Including the development of facilities for oxygen and heat, the employment effects increase to over 800 man-years nationally.

– A large proportion of these effects will occur in Bodø and the Salten region. The construction and operation of the hydrogen factory are expected to provide 320 man-years locally, and including facilities for heat and oxygen, the estimated employment effects are in the order of 370 man-years. This means that nearly half of the employment effects are expected to come locally, says Carl Erik Nyvold, team leader for analysis at KPB.

Bodø contractor Moldjord and GreenH have been collaborating for some time regarding the construction of the plant. Moldjord currently has 65 employees.

– A project of this magnitude will mean a lot to us, especially in the challenging market situation we are in. For us, it means that the trend will turn upwards, and we will see a normalization of the market situation, so that we can maintain activity at the level we desire. We will be able to turn development back to where it was before the pandemic and the war in Ukraine, says Finn Nikolaisen, managing director of Moldjord.

Effects both in construction and operational phases

KPB’s calculation is twofold, one part concerning the construction phase and the other the operational phase.

– It’s especially within the industrial and construction sectors where most of the man-years associated with the construction phase will be. Both industry and construction include a range of disciplines. Technical services will also have several direct deliveries to the project, Nyvold of KPB explains.

The construction phase of the hydrogen factory in Bodø is expected to have an employment effect of about 380 man-years in Norway. Including work on facilities for oxygen and heat, the total is 410 man-years.

It is expected there will be 16 – 20 full-time employee annually in the operational phase. About 60 percent of these are expected to come locally. Considering that the hydrogen factory is planned to have a 20-year lifespan, the employment effects in the operational phase will total over 300 full-time employees.

A catalyst for Bodø

GreenH aims to build leading expertise in Bodø and is also concerned with those effects that cannot be quantified.

– We want to contribute to making Bodø a hydrogen hub in Norway and Northern Europe, with all that entails. The hydrogen plant can, for example, make Bodø a relevant test base for the future of green aviation, and it could make it more interesting for Bodø youth to take engineering educations in green energy, says Bukkholm.

KPB emphasizes that the project can also have several other effects that cannot be quantified. For example, GreenH’s hydrogen factory may attract other business establishments and contribute to investments in other industries, says Nyvold at KPB.

The establishment of the hydrogen factory has a budget of 1 billion Norwegian kroner. Of this, Norwegian deliveries are expected to account for just over 600 million kroner. Local deliveries are estimated at about 370 million kroner.

Key facts about the project::

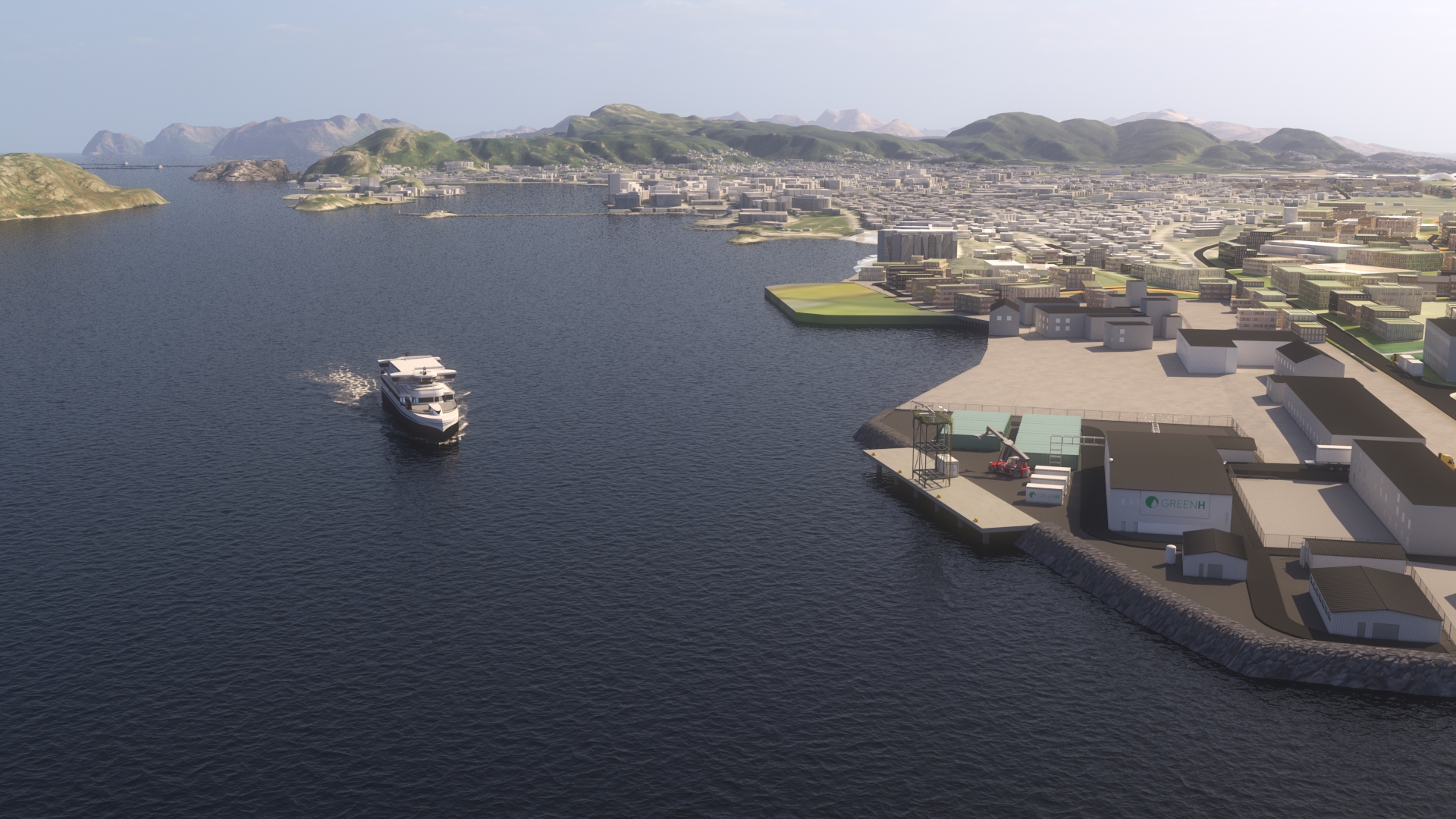

- Locally produced hydrogen for ships, road traffic, industry, and the new airport. The facility will have a capacity of 6-10 tons of hydrogen per day.

- 60 m quay connected to the factory where ships can easily bunker hydrogen.

- From the tanks, the hydrogen is transferred to a bunkering facility/tower on the quay. New technology for bunkering directly from the plant.

- The electrolysis process produces hydrogen, oxygen, and heat using water and renewable electricity as input factors.

- In the production of green hydrogen via electrolysis, heat is generated that must be removed. This resource is rarely utilized, and GreenH plans to transfer it to district heating systems and provide heat to the new district and airport coming to Bodø.

- The large amounts of oxygen created in the production process can be useful for the surrounding aquaculture industry.

- The direct man-years will primarily occur in Bodø, while the effects beyond this region will largely be indirect annual jobs and consumption effects.

- A facility of this magnitude requires large amounts of special equipment that must be purchased from abroad. The construction work will largely be carried out by local contractors.

This article is translated by ChatGPT and quality assured by the author.